A low sag factor in a metal ceramic fpd and cause.

Low sag factor in a metal ceramic.

Sag is an acronym for semi autogenous grinding.

Base metal dental alloys are often used as alternatives to precious alloys due their cost considerations mechanical properties and low density 1 2 currently there is growing concern about nickel ni being an allergen and beryllium be being a toxic element 3 4 therefore cobalt chromium co cr alloys may serve as an alternative to nickel chromium ni cr alloys due to the.

There are a wide range of ceramic coating materials that can be applied to metal components in order to enhance their functional properties.

B 1 and 4.

Most ceramic coatings are electrically nonconductive making them excellent insulators have a significantly higher level of abrasion resistance than most metals and are capable of maintaining their integrity under severely elevated temperatures.

4 poor metal ceramic bond strength.

1 flow of metal under functional load.

The largest sag mill is 42 12 8m in diameter powered by a 28 mw 38 000 hp motor.

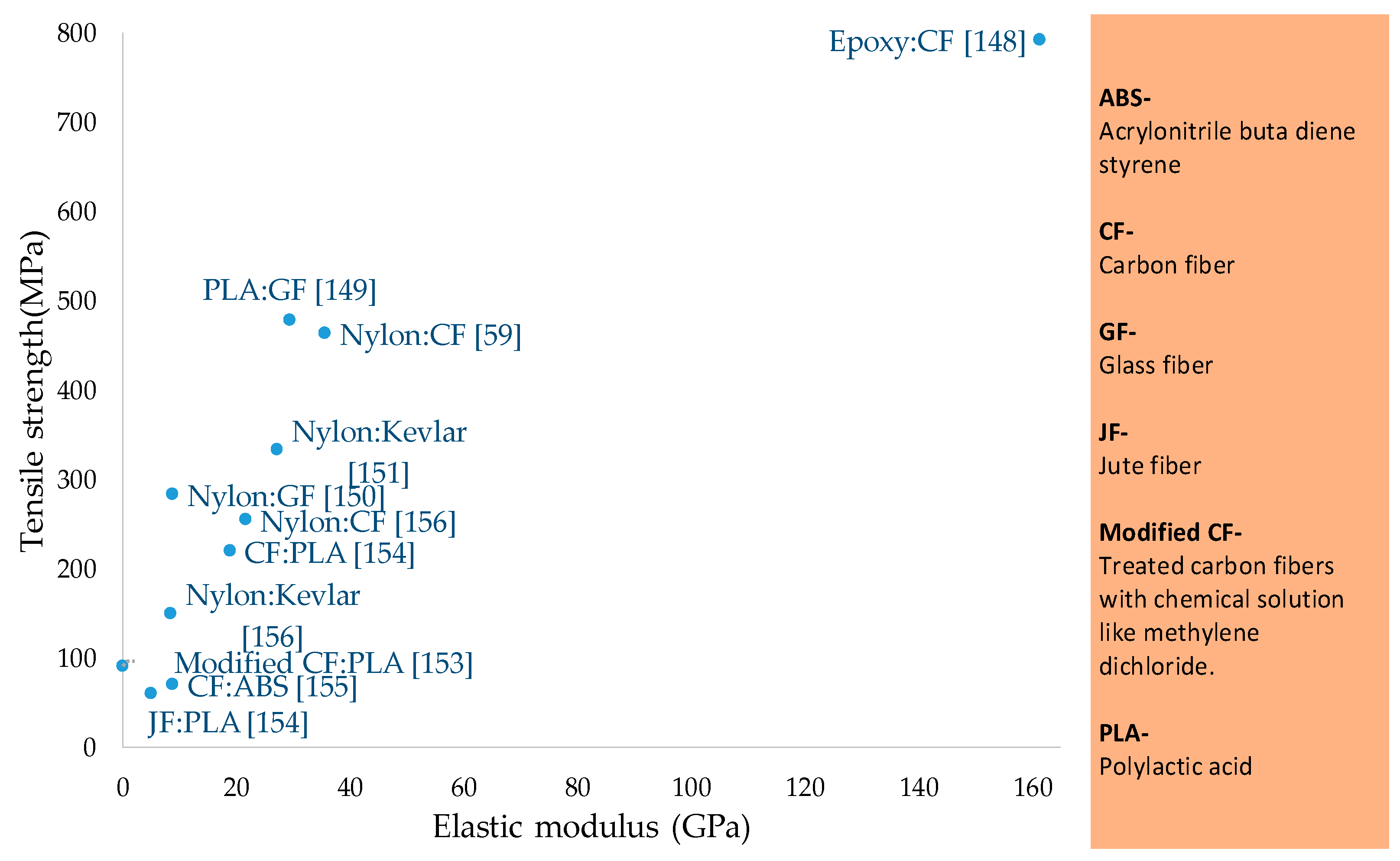

The ni cr alloys have the high elastic moduli and this decreases flexibility to less than half that of a framework of the same dimensions made of high gold alloy.

A sag mill is usually a primary or first stage grinder.

Low loss ceramic materials used in the circuit improves its overall quality factor by reducing the insertion loss and the power dissipation which suppresses the electrical noise in oscillators.

3 less deformation of bridge spans when fired.

The higher fusion temperatures of ni cr and co cr base metal alloys has been a factor that contributed to their superior sag resistance in comparison to the noble metal alloys.

2 high abrasion resistance.