We are aggressively working on updating the hundreds of cold formed framing details located in the cad library with updated product information.

Light guage metal shear wall details.

Updated clarkdietrich building system cad details can be found in the new clarkdietrich s itools cad library.

The details contained in this document are intended as a general guide for using steel stud manufacturers association ssma member products.

The steelsmart structural design suite provides construction professionals with the structural design software tools engineered for both fast and accurate design and detailing of light steel framing lsf studs and connectors.

Steelsmart structural design software suite for light steel framing.

Tables 1 through 3 are for walls with steel studs spaced at no more than 24 in.

No longer just a division between space.

M1 cabinet blocking detail m2 wiring and piping installation detail.

A er all of the perpendicular walls are connected.

B shape and dimensions as shown at left.

Sigmastud framing reinforce any holes added during the project construc on.

We see what the future for walls holds and we are acting on it with steel framing products that perform as a system backed by intelligent design tools and fully capable engineering services.

These products should not be used in design or construction without an independent evaluation by a qualified engineer or architect to verify the suitability.

Aisi d100 cold formed steel design manual aisi d110 cold formed steel framing design guide aisi d111 cold formed steel purlin roof framing systems being updated aisi d112 brick veneer cold formed steel framing design guide aisi d113 design guide for cold formed steel framed shear wall assemblies being updated.

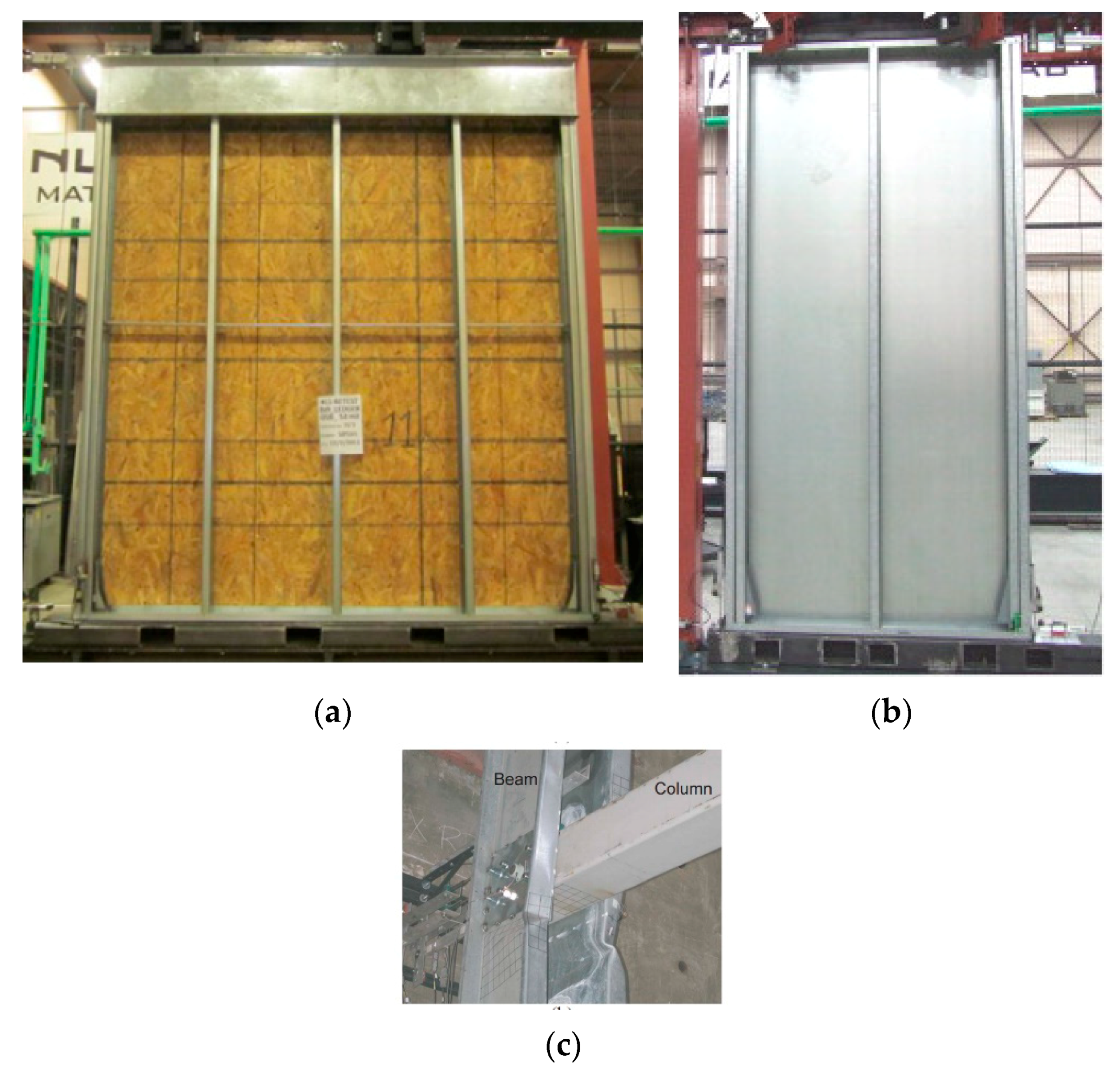

Table 3 is for seismic loads resisted by walls sheathed with plywood osb or steel sheet as indicated on one side only.

Wood and light gauge steel framed construction the diaphragms and shear walls called braced wall lines or braced wall panels in many codes and standards are constructed similarly.

Table 1 also includes walls sheathed with steel sheet on one side.

A er all permanent shear wall bracing is installed and l ghtened.

Review the detail at right for a possible solu on.

L temporary bracing should be designed by a design professional.

No longer just studs tracks and headers.

Light gauge steel meeting the physical and galvanization requirements of a s t m.

The details of the shear walls deviate from tested configurations in aisi s213 in that a a ledger or rim track is attached to the interior face of the walls b a gypsum board is attached to the interior face of the walls c osb panel seams do not always fall at stud or track locations and thus strapping must be used for shear transfer in.

Contact clarkdietrich technical services at 888 437 3244 for any questions on these details or if you.

Steelsmart raises the bar for the design and analysis of cold formed steel cfs by seamlessly.