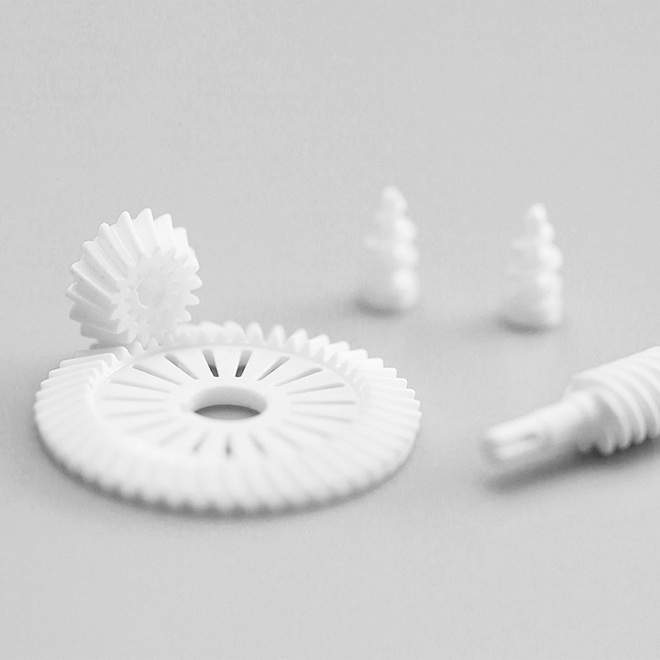

The lithography based ceramic manufacturing technology lcm an enhancement of dlp commercialized by lithoz gmbh is an am process for high performance and nearly dense ceramics with a high surface quality and a high resolution 635 dpi.

Lithography based ceramic manufacturing lcm.

Lithography based ceramic manufacturing lcm is used to make precise high quality components from ceramic materials which are used for example in micro electronics plasma technology and high temperature applications.

Lcm lithography based ceramic manufacturing.

The technology was initially developed at tu vienna more than a decade ago in 2006 by the same engineers who would go on to found lithoz in 2011.

From green body to precision work of art.

One of the most widely adopted methods for additively manufacturing high strength dense and accurate ceramics is lithography based ceramic manufacturing lcm.

A novel technique for additive manufacturing of high performance ceramics scientific net.

Ultraviolet lithography based ceramic manufacturing uv lcm of the aluminum nitride aln based photocurable dispersions by paulina ożóg 1 2 paweł rutkowski 2 dariusz kata 2 and thomas graule 1.

Our cerafab system fulfil even the highest requirements of high performance ceramics.

This technology is well suited to ceramic.

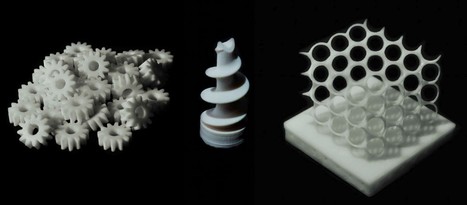

In this paper a new additive manufacturing technology the lithography based ceramic manufacturing lcm process is presented.

This technique is based on the selective curing of a photosensitive slurry by a mask exposure process.

Thus the achievable properties are similar to conventional manufacturing methods making the lcm technology an interesting complement for the ceramic industry.

In addition channels with varying diameters can be realized.

Lithography based ceramics manufacturing lcm lcm is a proprietary additive manufacturing technology developed by lithoz based on a dlp photopolymerization process.

The fraunhofer ikts uses the lithography based ceramic manufacturing lcm technology for the development of modified honeycombs with wall openings between and spoilers inside the different channels to combine enhanced mass transfer and low pressure drop.

Alumina toughened zirconia is a very interesting material for medical.